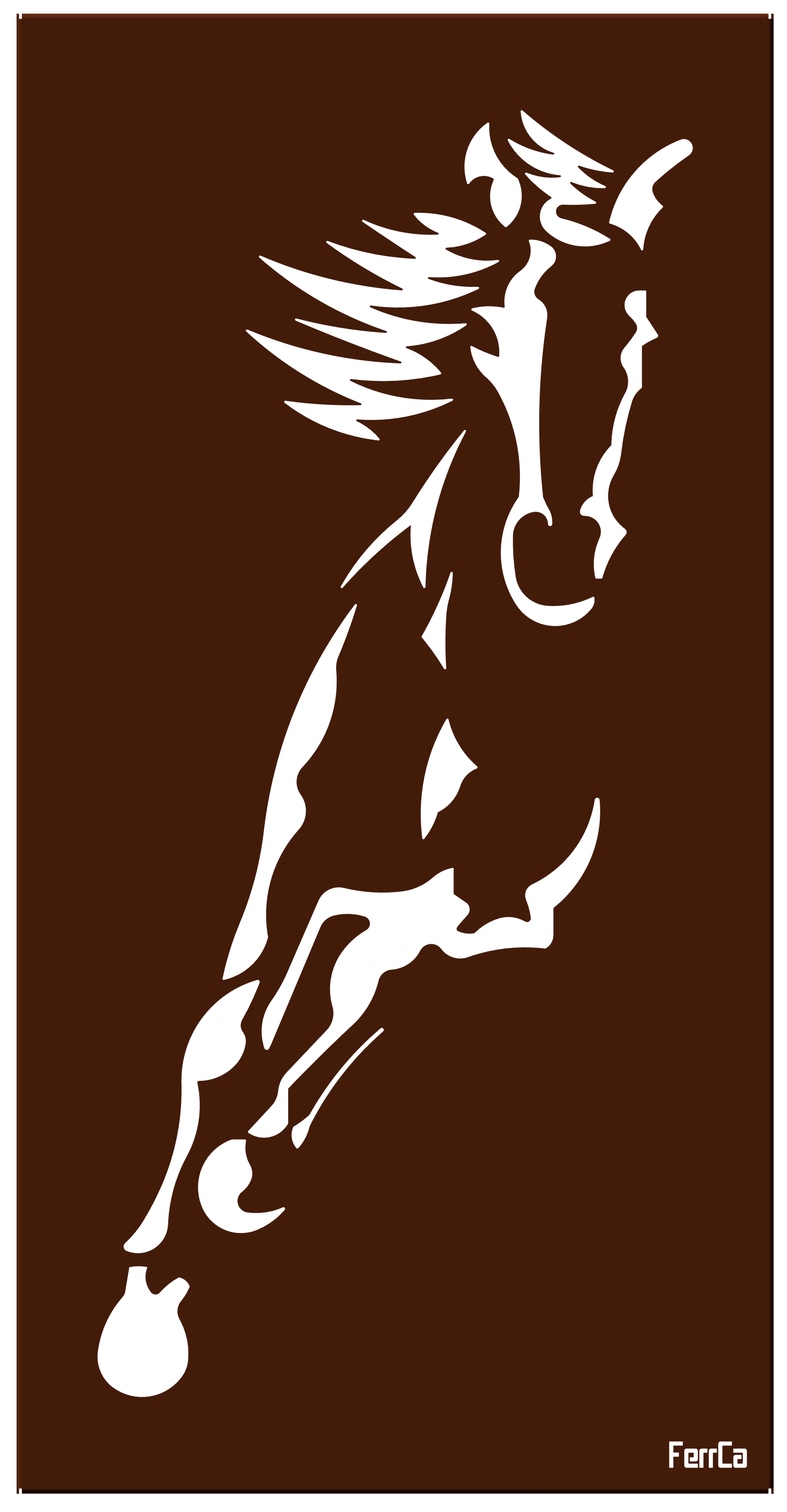

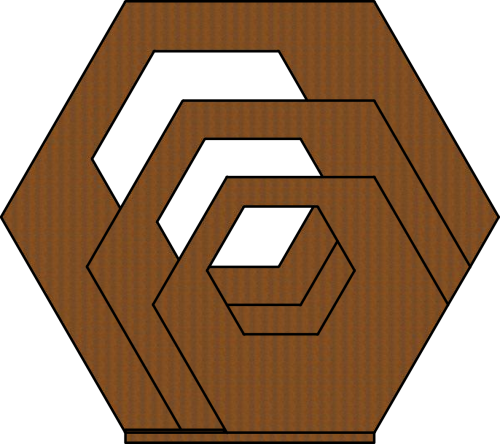

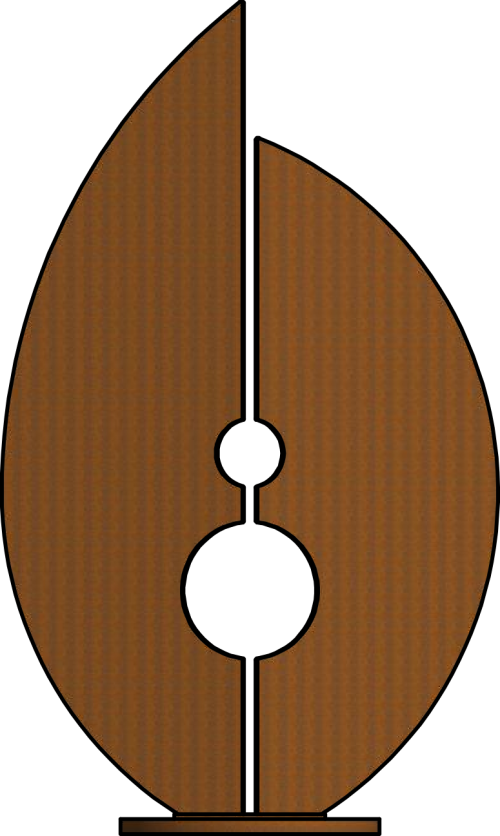

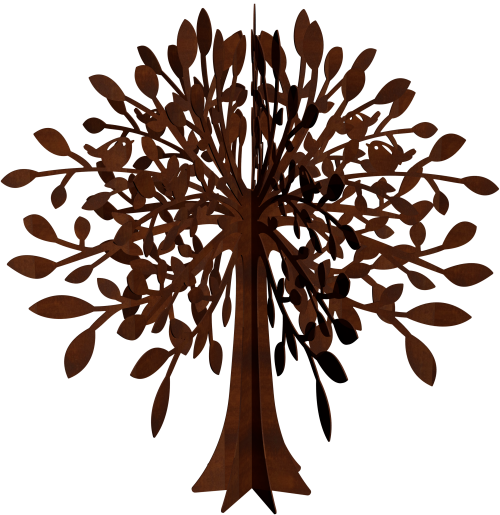

Horse made of corten steel

Product Short Description

Horse made of 3 mm corten steel

Delivery within 4 weeks

Paard gemaakt uit 3 mm cortenstaal

Levering binnen 4 weken

Cheval en 3 mm acier corten

Livraison sous 4 semaines

Pferd aus 3 mm Cortenstahl

Lieferung innerhalb von 4 Wochen

Caballo fabricados en 3 mm acero corten

Entrega en 4 semanas

Cavallo realizzati in 3 mm acciaio corten

Consegna entro 4 settimane

€ 1.799,00

Description

Horse made of corten steel

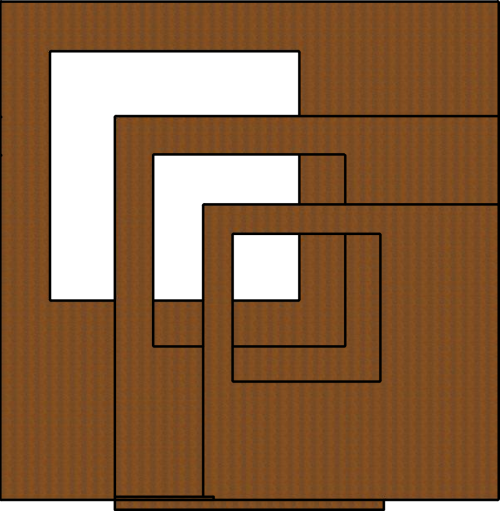

The Living Art of Corten SteelHorse made of corten steel

Corten steel, also known as weathering steel, is more than just a material—it’s a medium of transformation. Artists and designers use it to create sculptures that evolve over time, shaped by the natural elements. Unlike traditional materials, corten steel doesn’t remain static; instead, it changes, breathes, and matures.

Nature as a Co-CreatorHorse made of corten steel

Once exposed to the weather, corten steel begins to develop a unique patina. Wind, rain, and sunlight interact with the surface, gradually forming a protective rust layer. This process takes between three and nine months, depending on the climate. As a result, the final appearance—ranging from deep orange to earthy brown—varies based on temperature, humidity, and the sculpture’s position in space.

A Material That Tells a StoryHorse made of corten steel

Each corten steel artwork becomes a one-of-a-kind creation. Therefore, no two pieces look the same, even if they start from the same design. In fact, the environment writes its own story on the surface, making the artwork a collaboration between artist and nature. Moreover, this unpredictability adds depth and meaning to the final result.

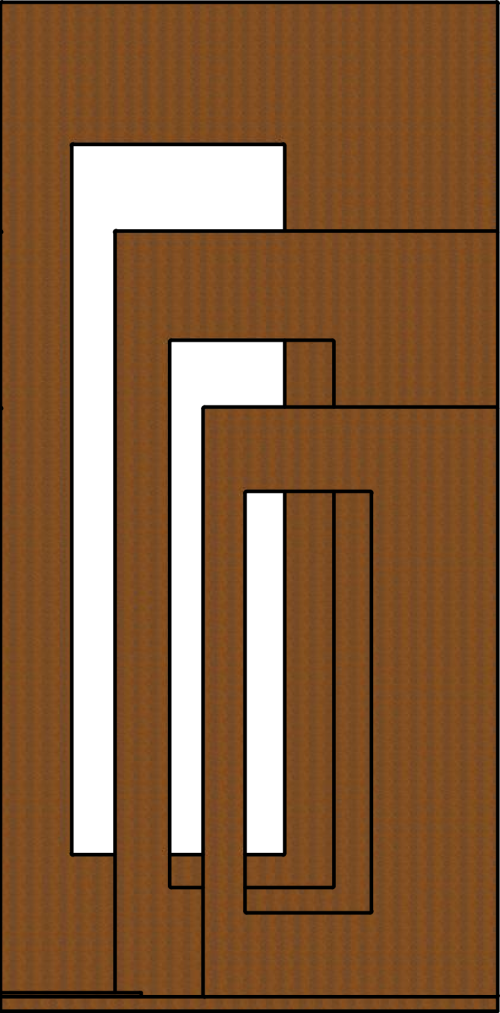

Embracing Change and Impermanence

Artists who work with corten steel embrace its evolving nature. They don’t just shape the material—they invite it to change. Over time, the sculpture gains character, reflecting the passage of seasons and the rhythm of the weather. Consequently, corten steel becomes ideal for outdoor installations that aim to connect with their surroundings.

Art That Lives and Breathes

Corten steel transforms art into a living experience. It resists corrosion while celebrating decay. In addition, it invites viewers to reflect on time, transformation, and the beauty of impermanence. Ultimately, in corten steel, art is not frozen—it is alive, ever-changing, and deeply connected to the world around it.

Horse made of corten steel

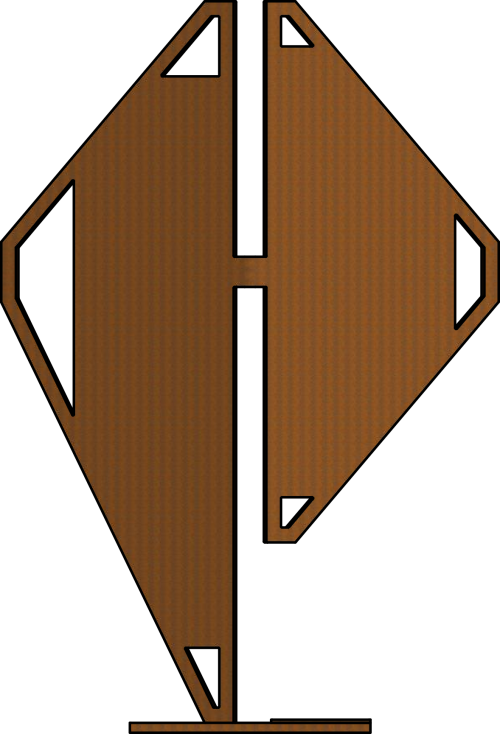

Additional information

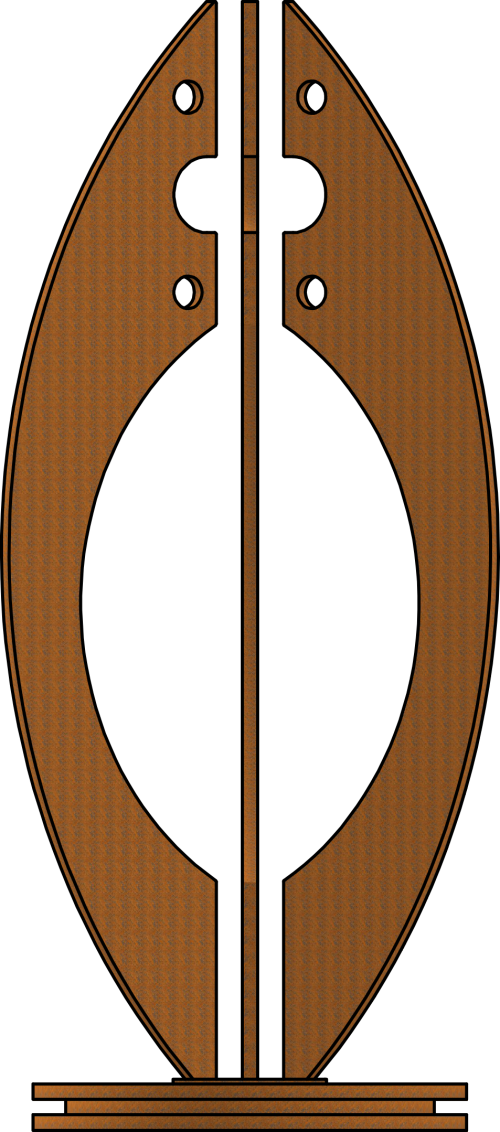

| Weight | 36 kg |

|---|---|

| Dimensions | L 87 x W 3 x H 170 cm |

Blootgesteld aan het weer, zal dit materiaal een eigen leven gaan leiden. De kleuren veranderen en creëren nieuwe beelden. De uiteindelijke kleur is afhankelijk van temperatuur, vochtigheid en de specifieke positie van het product. De vorming van de definitieve barrièrelaag duurt – afhankelijk van klimaat en weersomstandigheden – ongeveer 3 tot 9 maanden.

Exposée à la météo, cette matière commencera à déployer sa propre vie. Les couleurs changent et créent de nouvelles images. La couleur finale dépendra de la température, de l’humidité et de la position exacte du produit. La formation de la couche barrière finale prend – selon le climat et les conditions météorologiques – environ 3 à 9 mois.

Der Witterung ausgesetzt, beginnt dieses Material ein Eigenleben zu entfalten. Die Farben verändern sich und erzeugen neue Bilder. Die endgültige Farbe hängt von Temperatur, Luftfeuchtigkeit und der jeweiligen Position des Produkts ab. Der Aufbau der endgültigen Sperrschicht dauert – je nach Klima- und Witterungsverhältnissen – ca. 3 bis 9 Monate.

Expuesto a la intemperie, este material comenzará a desarrollar una vida propia. Los colores cambian y crean nuevas imágenes. El color final depende de la temperatura, la humedad y la posición particular del producto. La formación de la capa de barrera final tarda, según el clima y las condiciones meteorológicas, entre 3 y 9 meses aproximadamente.

Esposto alle intemperie, questo materiale inizierà a sviluppare una vita propria. I colori cambiano e creano nuove immagini. Il colore finale dipende dalla temperatura, dall’umidità e dalla particolare posizione del prodotto. La formazione dello strato barriera finale richiede, a seconda del clima e delle condizioni atmosferiche, circa 3-9 mesi.